Understanding the Benefits of Table CNC Machines for Modern Manufacturing

As modern manufacturing continues to evolve, the adoption of innovative technologies such as table CNC machines has become increasingly vital. According to a recent report by Grand View Research, the global CNC machine market is projected to reach USD 100 billion by 2025, fueled by the growing demand for automation in manufacturing processes. Table CNC machines, in particular, are redefining precision and efficiency in production environments across various industries. These machines enable manufacturers to perform complex tasks with minimal human intervention, thereby reducing production time and ensuring high-quality output. However, as industries embrace this technology, they also face challenges, including the need for skilled operators and concerns over initial investment costs. Understanding both the benefits and the potential problems associated with table CNC machines is essential for manufacturers looking to remain competitive in a fast-paced market.

Advantages of Table CNC Machines in Precision Engineering and Production

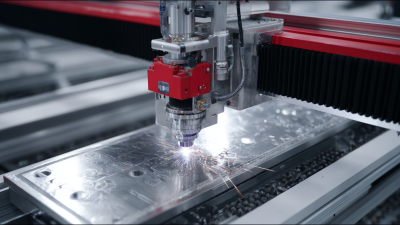

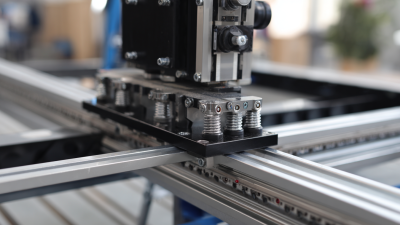

Table CNC machines have become indispensable tools in modern manufacturing, particularly in the realm of precision engineering and production. Their ability to automate complex machining processes significantly enhances accuracy and efficiency, allowing manufacturers to create intricate designs without compromising on quality. The precision offered by these machines is crucial in industries where tolerances are tight, which is increasingly vital as the demand for more sophisticated products rises.

One of the primary advantages of table CNC machines is their versatility. They are capable of performing a wide range of operations, from milling and drilling to engraving and cutting, on various materials such as metals, plastics, and composites. This adaptability not only streamlines production workflows but also reduces the need for multiple machines, ultimately cutting costs. As the CNC machine tools market is projected to grow at a CAGR of over 10.3% until 2032, manufacturers are poised to invest more in these technologies, further driving innovation in precision engineering and enhancing production capabilities.

Impact of Table CNC Technology on Manufacturing Speed and Efficiency

Table CNC machines have revolutionized modern manufacturing by significantly enhancing speed and efficiency. According to a report by Grand View Research, the global CNC machine market is expected to reach $100 billion by 2025, driven by the rising demand for automation in manufacturing processes. Table CNC machines allow for precise automation of cutting, drilling, and milling operations, streamlining production workflows. This precision translates to reduced cycle times and higher output rates, which is essential for industries facing increasing time-to-market pressures.

Implementing table CNC technology not only improves operational efficiency but also minimizes material waste. A study published by the International Journal of Advanced Manufacturing Technology found that manufacturers using CNC machines can achieve up to 30% more efficiency compared to traditional machining methods. This efficiency gain can be attributed to the consistent quality and repeatability that CNC machines provide, enabling manufacturers to maintain tighter tolerances and reduce rework.

**Tip:** When integrating table CNC machines into your production line, ensure proper training for operators to maximize the benefits of the technology. Regular maintenance is also key—consider scheduling machine check-ups every 300-500 hours of operation to maintain peak performance. **Tip:** Analyze your workflow for automation opportunities; even small modifications can lead to significant improvements in productivity and efficiency.

Cost-Benefit Analysis: Investing in Table CNC Systems vs. Traditional Methods

Investing in table CNC machines can significantly enhance the efficiency and accuracy of manufacturing processes compared to traditional methods. While the initial investment may seem daunting, a thorough cost-benefit analysis reveals that the long-term savings on labor and materials often outweigh the upfront costs. CNC machines reduce human error and increase production speed, leading to higher output and reduced waste—essential factors in staying competitive in today’s market.

**Tips**: When considering a table CNC system, evaluate the total operational costs, including maintenance and training. Additionally, consider the scalability of your current operations—CNC systems can easily adapt as production demands grow, ensuring a more sustainable investment.

Another critical aspect is the technology’s ability to produce complex designs with precision. Unlike traditional machining, CNC systems can easily manage intricate patterns and cuts without sacrificing quality. This capability opens new avenues for creativity and customization, allowing manufacturers to meet diverse client needs effectively.

**Tips**: Keep the end-user in mind when selecting CNC software and tools. A user-friendly interface can drastically reduce training time for your team and enhance productivity from the onset.

Cost-Benefit Analysis of CNC Machines vs. Traditional Manufacturing Methods

Trends in Table CNC Machine Adoption Across Different Industries

The adoption of Table CNC machines is rapidly transforming various industries, driven by advancements in digital manufacturing technologies. A recent report estimates that the market for 3-Axis and 5-Axis CNC Vertical Machining Centers was valued at USD 11.41 billion in 2024, indicating robust growth potential. This surge is attributed to the increased demand for precision machining across sectors such as aerospace, automotive, and electronics, where efficiency and accuracy are paramount.

Furthermore, the global machine tools market is projected to grow from USD 81.09 billion in 2025 to an impressive USD 105.11 billion by 2030, reflecting a compound annual growth rate (CAGR) of 3.8%. This growth underscores a significant shift towards the integration of automated solutions, including CNC technology, which streamlines production processes. As industries evolve, the adoption of Table CNC machines is seen as a pivotal move towards enhancing productivity and meeting the complex demands of modern manufacturing.

Real-World Case Studies: Successful Implementation of Table CNC Solutions

In modern manufacturing, the implementation of Table CNC machines has proven transformative through numerous real-world case studies. Companies across various industries have harnessed the precision and efficiency of CNC technology to streamline their operations and optimize production processes. For instance, a furniture manufacturer in North Carolina recently adopted a Table CNC machine, significantly reducing production time while enhancing the quality of their custom designs. This case highlights how CNC solutions can lead to substantial improvements in both speed and craftsmanship.

Tip: When considering a Table CNC solution, assess your specific manufacturing needs and the scale of production. Matching the capabilities of the CNC machine with your design requirements is essential for maximizing efficiency.

Another compelling example is a small metal fabrication shop that integrated CNC technology to reduce waste and improve accuracy in cutting complex shapes. By switching to a Table CNC system, they managed to fulfill more complex client orders without sacrificing turnaround times. Such implementation not only enhanced customer satisfaction but also expanded their market reach.

Tip: Regular training and upskilling of your team in CNC operations can greatly enhance productivity and minimize downtime. Encouraging continuous learning allows your workforce to adapt quickly to evolving manufacturing technologies.

Understanding the Benefits of Table CNC Machines for Modern Manufacturing

| Case Study | Industry | Key Benefits | Production Increase (%) | Cost Reduction (%) |

|---|---|---|---|---|

| Case Study A | Automotive | Precision machining, faster lead times | 30% | 25% |

| Case Study B | Aerospace | Improved accuracy, higher quality parts | 25% | 20% |

| Case Study C | Medical Devices | Enhanced customization, reduced waste | 40% | 30% |

| Case Study D | Electronics | Faster prototyping, reduced setup times | 35% | 22% |

Related Posts

-

7 Best Industrial CNC Machines Revolutionizing Precision Manufacturing Today

-

Finding Quality Suppliers for Best Industrial Cutting Tables Effective Strategies for Global Buyers

-

Solutions for Optimizing Your Workflow with the Best Small CNC Plasma Cutting Machines

-

Understanding the Specifications of the Best Industrial CNC Plasma Table and How to Use It

-

How to Maximize After-Sales Support for the Best CNC Table and Minimize Repair Costs

-

Maximizing ROI on Best Industrial CNC Plasma Tables: How Superior After-Sales Service and Low Maintenance Costs Drive Success