How to Choose the Best Small CNC Plasma Cutting Machine for Your Business Needs

In the rapidly evolving landscape of manufacturing, the demand for precision and efficiency has led to a significant increase in the use of small CNC plasma cutting machines. According to recent market reports, the global CNC plasma cutting machines market is projected to grow at a compound annual growth rate (CAGR) of over 5% through the next five years, driven by the need for advanced cutting technologies in various industries, including automotive and metal fabrication. For businesses looking to enhance their production capabilities, selecting the right small CNC plasma cutting machine can be a crucial decision. Factors such as machine size, cutting speed, and software compatibility play vital roles in determining the best fit for specific business needs. This guide aims to provide essential tips and insights into choosing the ideal small CNC plasma cutting machine, ensuring that your investment aligns with operational demands and quality expectations.

Understanding Your Business Requirements for CNC Plasma Cutting

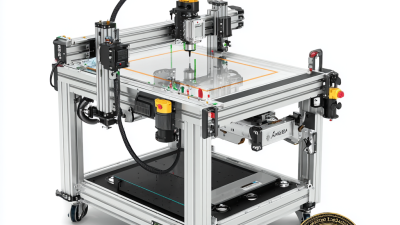

When selecting the best small CNC plasma cutting machine for your business, it is essential to understand your specific operational needs. Assess the types of materials you intend to cut, their thickness, and the precision required for your projects. For instance, if your business focuses on detailed artwork or intricate designs, investing in a machine with advanced capabilities and higher precision would be beneficial. Alternatively, if you aim to produce more straightforward cuts for larger structures, a more basic model may suffice.

Tips to consider include evaluating the machine’s compatibility with various software and ensuring it supports the production volume you anticipate. Also, think about your workspace; a compact machine may be ideal for smaller shops, while a larger operation might warrant a more robust setup. Moreover, consider the anticipated growth of the CNC plasma cutting market, projected to reach approximately $958 million by 2030. This growth indicates increased demand, emphasizing the importance of selecting a reliable and efficient machine that can adapt to your changing business needs.

Key Features to Look for in a Small CNC Plasma Cutting Machine

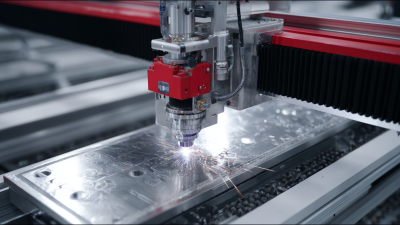

When selecting a small CNC plasma cutting machine for your business, it's vital to understand key features that can significantly enhance your operations. Firstly, consider the cutting capacity and thickness. Look for machines that can handle the materials you'll be working with, ensuring they provide the versatility needed for different projects. A machine with adjustable cutting speeds can also greatly aid efficiency by allowing you to optimize the process according to material type and thickness.

Moreover, precision and control are paramount in plasma cutting. Evaluate machines that offer advanced CNC controls, which can ensure accurate cuts and repeatability. Features such as motion control systems, height control for consistent plasma arc distance, and software compatibility will drastically improve the overall cutting performance. Given the rapid growth projected for the plasma cutting machine market, it’s essential to invest in technology that will not only meet your current requirements but also adapt to future trends and innovations in the industry.

Comparing Popular Brands and Models in the Market

When considering a small CNC plasma cutting machine for your business, it's essential to compare various popular brands and models in the market. Recent industry reports highlight that the small CNC plasma cutting machine market is expected to grow at a CAGR of 5.3% from 2021 to 2026, driven largely by rising demand in sectors like automotive, aerospace, and fabrication. Prominent brands such as Hypertherm, Lincoln Electric, and Esab consistently rank high due to their reliability and advanced technology features. For example, Hypertherm's Powermax series is known for its superior cut quality and efficiency, making it a favorite among small businesses.

Moreover, understanding the specifications of different models can significantly enhance your decision-making process. Many manufacturers now offer machines equipped with advanced CNC controls and software, which streamline operations and improve precision. A 2022 report from the Fabricators & Manufacturers Association revealed that businesses utilizing CNC plasma cutters report a 30% increase in production speed and a 20% reduction in waste material compared to traditional cutting methods. This places emphasis on selecting a machine that not only meets your immediate needs but also keeps pace with future developments in the industry.

How to Choose the Best Small CNC Plasma Cutting Machine for Your Business Needs

| Model | Cutting Area (inches) | Max Cutting Thickness (inches) | Max Cutting Speed (ipm) | Power Requirements (V) | Weight (lbs) | Price Range ($) |

|---|---|---|---|---|---|---|

| Model A | 24 x 24 | 1/2 | 600 | 220 | 150 | 3000 - 4000 |

| Model B | 36 x 36 | 3/8 | 800 | 240 | 200 | 4000 - 5000 |

| Model C | 48 x 48 | 1 | 900 | 220 | 250 | 5000 - 6000 |

| Model D | 30 x 30 | 3/16 | 700 | 220 | 175 | 2500 - 3500 |

Budget Considerations: Finding the Right Price for Quality

When selecting a small CNC plasma cutting machine, budget considerations play a crucial role in ensuring you make the right investment for your business. The ideal machine should strike a balance between cost and quality, allowing you to cut expenses without sacrificing performance. Start by determining your budget range while keeping in mind the essential features you need for your operations. A lower initial investment may seem enticing, but beware of hidden costs linked to inadequate capabilities or subpar customer support.

To find the right price for quality, it's essential to explore different brands and models while reading user reviews and expert opinions. This research will give you insight into the value each machine offers in relation to its price. Don’t forget to consider additional expenses like consumables, maintenance, and potential upgrades, as these can impact your overall budget. By carefully evaluating your needs and the long-term costs associated with different machines, you can confidently choose an affordable yet efficient CNC plasma cutter that aligns with your business goals.

Maintenance and Support: Ensuring Longevity of Your Equipment

When selecting a small CNC plasma cutting machine for your business, prioritizing maintenance and support is crucial for ensuring the longevity and efficiency of your equipment. According to a recent industry report by Grand View Research, the CNC machining market is expected to reach $100 billion by 2025, emphasizing the importance of reliable machinery in a competitive landscape. Regular maintenance not only improves cutting precision but also reduces downtime, maximizing productivity.

**Tip:** Develop a routine maintenance schedule that includes daily cleaning and monthly inspections. Keeping filters clean and checking for wear on consumables can significantly extend the life of your plasma cutter.

Furthermore, consider the availability of customer support from the manufacturer. A study from Statista indicates that 88% of customers are less likely to return to a brand after a poor service experience. Ensure that your chosen supplier offers robust technical support and easy access to replacement parts, as this will minimize disruptions to your workflow and maintain operational efficiency.

**Tip:** Establish a rapport with your equipment supplier and seek out user forums or community support groups. Connecting with other users can provide invaluable insights into best maintenance practices and troubleshooting common issues.

Related Posts

-

Exploring the Future of Precision: The Evolution of Small CNC Plasma Cutting Machines

-

Discover Premier CNC Plasma Cutting Solutions from Leading Chinese Manufacturers for Global Markets

-

7 Key Advantages of Choosing the Best Plasma Cutting Machine for Your Business

-

How to Navigate Import and Export Certifications for Best Small Plasma Tables

-

Solutions for Optimizing Your Workflow with the Best Small CNC Plasma Cutting Machines

-

7 Best Industrial CNC Machines Revolutionizing Precision Manufacturing Today