Unlocking Efficiency: The Unique Advantages of Small Plasma Cutting Tables in Modern Manufacturing

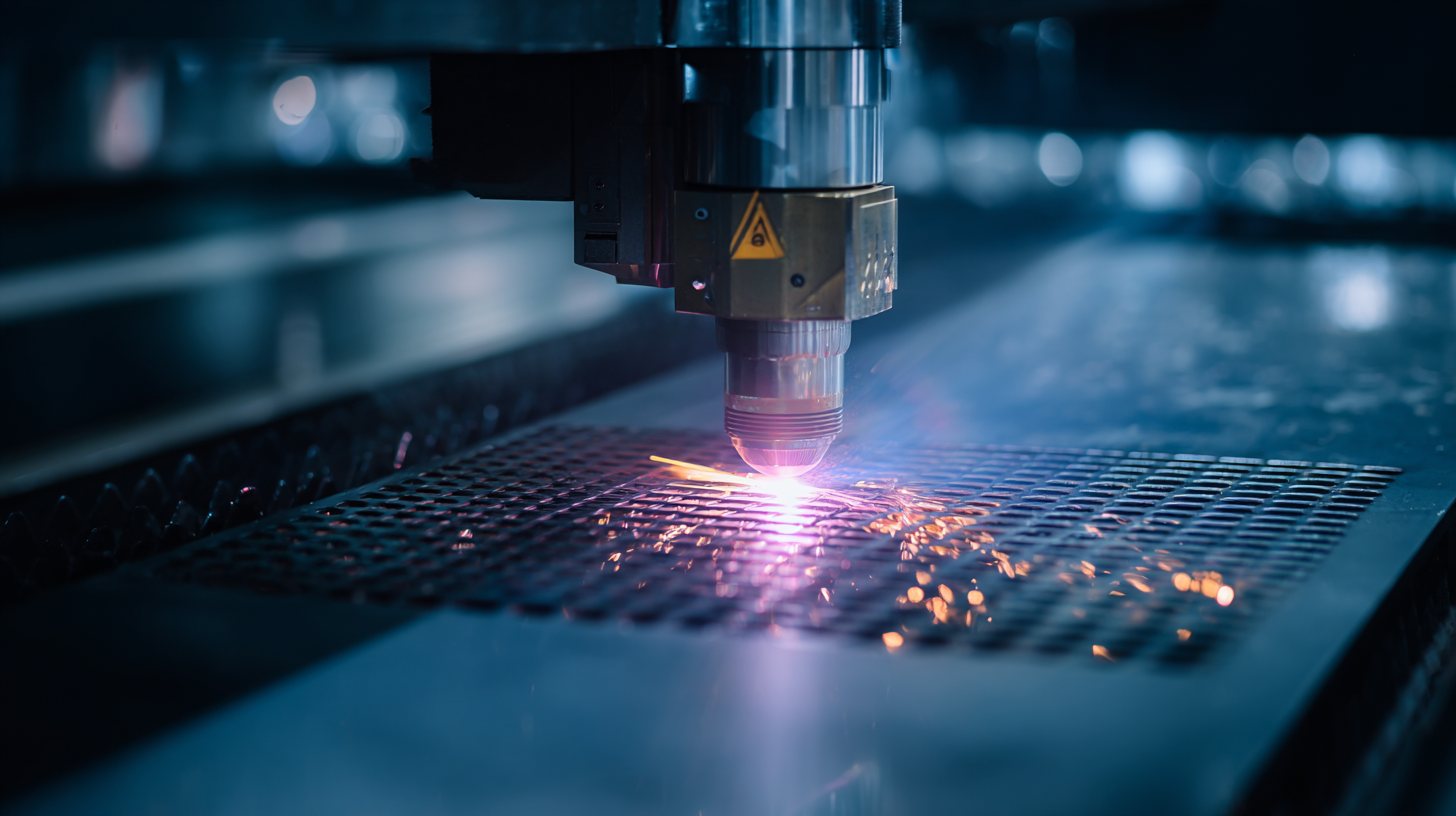

In the fast-paced world of modern manufacturing, the demand for efficiency and precision has never been higher. According to a recent report by Research and Markets, the global plasma cutting market is projected to reach $5.5 billion by 2025, driven by advancements in technology and the increasing need for high-quality cutting solutions across various industries. Within this evolving landscape, **small plasma cutting tables** have emerged as a transformative tool, offering unique advantages that cater specifically to the needs of small to medium-sized businesses. These compact machines not only enhance operational efficiency but also provide cost-effective solutions without sacrificing quality or precision. As manufacturers seek to optimize their processes, embracing the capabilities of small plasma cutting tables may prove to be a vital step towards achieving sustainable growth and competitiveness in an increasingly crowded marketplace.

Benefits of Compact Plasma Cutting Tables: Boosting Operational Efficiency

Compact plasma cutting tables are rapidly becoming a favored choice in modern manufacturing environments, primarily due to their numerous operational benefits. These smaller machines are designed to fit into tight spaces, making them ideal for workshops where every square foot counts. The compact design doesn’t sacrifice cutting power; instead, it provides manufacturers with the ability to perform precise cuts with minimal material wastage. This efficiency can lead to significant cost savings and quicker turnaround times on projects.

Moreover, small plasma cutting tables are user-friendly and often equipped with advanced technology that streamlines the cutting process. These tables can be easily integrated into existing workflows, allowing for smoother operations and reducing the learning curve for new users. Their versatility means they can handle various materials effectively, from metals to plastics, making them suitable for a wide range of applications. By boosting operational efficiency through improved space utilization and enhanced cutting capabilities, compact plasma cutting tables are transforming the way manufacturers approach production.

Unlocking Efficiency: Benefits of Compact Plasma Cutting Tables

Key Industry Stats: Plasma Cutting Market Growth and Demand Trends

The plasma cutting market is experiencing significant growth, reflecting broader trends in the manufacturing sector. Key industry statistics indicate that the global art tools market is projected to expand from $3.61 billion in 2023 to $5.44 billion by 2030, exhibiting a compound annual growth rate (CAGR) of 6.04%. This surge highlights the growing demand for efficient, precise, and versatile tools in various applications, including metal fabrication.

As industries increasingly turn to advanced technologies, small plasma cutting tables emerge as game-changers. These compact machines not only enhance operational efficiency but also cater to the rising preferences for space-saving solutions in manufacturing environments. Additionally, the metal cutting tools market is expected to grow from $86.24 billion in 2025 to $141.65 billion by 2032, driven by innovations that optimize cutting processes and reduce waste. The evolving landscape emphasizes the need for agile manufacturing capabilities, which are bolstered by the advantages offered by smaller plasma cutting systems.

Cost-Effectiveness of Small Plasma Cutting Solutions for Manufacturers

In today’s competitive landscape, cost management is essential for manufacturers seeking to optimize production processes. Small plasma cutting tables present an innovative solution, offering significant cost-effectiveness without sacrificing quality. These compact systems require less initial investment compared to large industrial machines, making them accessible to small and medium-sized enterprises. By streamlining operations and reducing overhead costs associated with larger equipment, manufacturers can allocate resources more efficiently, ultimately boosting profitability.

Moreover, small plasma cutting solutions enhance operational flexibility. Their compact design allows for easier setup and relocation within the shop floor, enabling manufacturers to adapt to changing production demands swiftly. Because these machines consume less energy and require fewer consumables, ongoing operational costs are minimized, providing long-term savings. This efficiency is further amplified when considering the reduction in material waste due to the precision of plasma cutting, ensuring manufacturers achieve optimal yields from their raw materials. By investing in small plasma cutting tables, companies not only cut costs but also reinforce their competitive edge in a rapidly evolving market.

Unlocking Efficiency: The Unique Advantages of Small Plasma Cutting Tables in Modern Manufacturing

| Feature | Description | Cost Savings (%) | Efficiency Improvement (%) | Common Applications |

|---|---|---|---|---|

| Compact Design | Small footprint, suitable for limited space | 15% | 20% | Metal Fabrication |

| Lower Initial Investment | More affordable for small-to-medium enterprises | 20% | 15% | Artistic Designs |

| Portability | Easier to transport and setup for different jobs | 10% | 25% | Construction Sites |

| Energy Efficiency | Lower power consumption compared to larger models | 30% | 18% | Small Parts Cutting |

| User-Friendly Operation | Designed for ease of use with minimal training | 5% | 10% | Hobbyist Projects |

Precision and Versatility: Small Tables vs. Traditional Plasma Cutters

In the realm of modern manufacturing, the choice between small plasma cutting tables and traditional plasma cutters has become increasingly significant.

Small plasma cutting tables offer unparalleled precision and versatility, making them ideal for a range of applications from prototyping to intricate designs. According to a report by IBISWorld, the plasma cutting industry has seen a growth rate of 3.7% annually, driven largely by the advancements in smaller, more efficient cutting solutions. These compact machines provide manufacturers with the ability to execute complex cuts with minimal waste, ensuring optimal use of materials.

The precision of small plasma cutting tables is particularly noteworthy, with capabilities that can achieve cut tolerances of ±0.5 mm. This level of accuracy not only reduces the risk of costly errors but also allows for intricate designs that were previously difficult to achieve with larger traditional cutters. Furthermore, small tables require less floor space, allowing manufacturers to optimize their shop layouts while maintaining high productivity levels. Industry experts suggest that as manufacturers increasingly prioritize agility and efficiency, the transition towards these smaller, more versatile machines will continue to gain momentum, reshaping the landscape of cutting technologies in manufacturing.

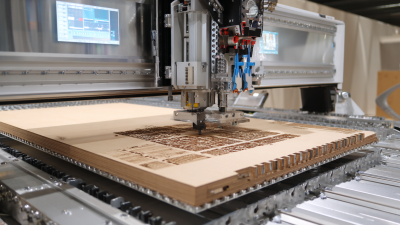

Space Optimization: How Small Plasma Tables Enhance Workflow in Workshops

In today’s manufacturing landscape, efficiency hinges not only on advanced technology but also on space optimization. Small plasma cutting tables have emerged as crucial tools for workshops seeking to maximize their workflow. According to a report by MarketsandMarkets, the global plasma cutting systems market is expected to grow from $4.1 billion in 2021 to $5.9 billion by 2026, with small cutting tables leading this growth due to their versatility and compact design. These tables allow for easy integration into limited spaces, enabling manufacturers to maintain high production rates without the need for expansive floor layouts.

Furthermore, the ergonomic design of small plasma tables facilitates a more streamlined production process. A study from the Fabricators & Manufacturers Association International (FMA) reveals that optimizing workspace can improve productivity by up to 20%. Workshops equipped with small plasma cutting systems report significant reductions in load times and enhanced material handling capabilities. This environment not only boosts efficiency but also fosters creativity and innovation, as operators have the freedom to rearrange their workspace to suit project needs, ultimately leading to faster turnaround times and increased job satisfaction.

Related Posts

-

Precision Engineering in China: Elevating Global Manufacturing with the Best Plasma Cutting Technology

-

7 Reasons Why the Best Industrial Plasma Table is an Essential Investment for Global Buyers

-

The Future of Precision with CNC Plasma Cutting Tables in Manufacturing

-

7 Best Industrial CNC Machines Revolutionizing Precision Manufacturing Today

-

2025 Global Purchasing Guide to Best CNC Table Advancements and Trends

-

Maximizing ROI on Best Industrial CNC Plasma Tables: How Superior After-Sales Service and Low Maintenance Costs Drive Success