5 Essential Tips for Choosing the Perfect Plasma Table for Your Business

In the rapidly evolving landscape of metal fabrication, choosing the right plasma table is crucial for businesses aiming to enhance productivity and precision. According to industry reports, plasma cutting technology is projected to witness a CAGR of over 6% through 2025, highlighting its increasing adoption across various sectors. A well-chosen plasma table not only streamlines operations but also improves cutting accuracy and material efficiency, directly impacting the bottom line. However, many businesses face challenges such as determining the right specifications, size, and features that align with their operational needs. By addressing common pitfalls and providing essential insights, this blog aims to equip business owners with the knowledge necessary to make informed decisions and select the perfect plasma table that meets both current demands and future growth potential.

Understanding Your Business Needs for a Plasma Table

When selecting the perfect plasma table for your business, it's vital to first understand your specific needs and requirements. The global plasma cutting machine market is projected to expand from $646.2 million in 2023 to $841.4 million by 2030, with a CAGR of 3.8%. This trend underscores the growing reliance on mechanized cutting solutions across various industries. As a business owner, you need to evaluate the scale and type of projects you undertake, the materials you frequently work with, and your production capabilities. A table that aligns with your operational demands will enhance efficiency and output quality.

Moreover, the evolution of mechanized plasma cutting from a simple tool to a sophisticated production asset reflects its importance in modern fabrication. Many self-employed fabricators kickstart their journeys with basic welding equipment, yet the demand for precision and productivity leads them to advanced solutions like plasma tables. As the CNC machine market is expected to witness substantial growth, transitioning to a plasma cutting table can position your business strategically in a competitive landscape. Understanding these market dynamics will empower you to make informed decisions that align with your business goals.

Key Features to Consider When Selecting a Plasma Table

When selecting the perfect plasma table for your business, it’s essential to focus on key features that can significantly influence your productivity and efficiency. One of the most critical aspects is the cutting area size. According to a report by Research and Markets, the demand for larger cutting tables has surged by over 20% in the last few years, as companies strive to optimize their workflow for bigger projects. Ensure that the table you choose can accommodate the dimensions of the materials you'll be working with to avoid limitations down the road.

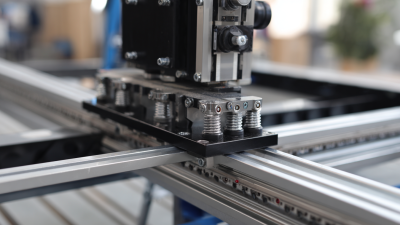

Another significant feature to consider is the table's compatibility with software systems. An advanced control system can greatly enhance precision. A survey from Fabricating and Metalworking indicates that businesses utilizing integrated CAD/CAM software with their plasma tables experience up to a 30% increase in productivity. When evaluating options, check for user-friendly interfaces and compatibility with your existing design tools, which can facilitate seamless integration and operation.

Lastly, don’t overlook the importance of build quality and durability. Investing in a plasma table constructed with robust materials can lead to substantial long-term savings. A study from the National Association of Manufacturers reveals that companies using high-quality machinery report fewer breakdowns and maintenance issues, resulting in a reduction in operational downtime by approximately 15%. Prioritize sturdy construction when making your choice to ensure consistent performance and longevity.

Comparing Different Types of Plasma Tables on the Market

When selecting a plasma table for your business, it's crucial to understand the various types available on the market. Plasma tables can broadly be categorized into three types: CNC plasma tables, handheld plasma cutters, and hybrid models. The CNC plasma tables are often preferred for their precision and efficiency, offering automation that enhances productivity. According to a recent industry report by IBISWorld, the CNC plasma cutting industry is projected to grow at an annual rate of 4.2% over the next five years, indicating a strong trend toward automated solutions in metal fabrication.

Handheld plasma cutters, while less expensive, are typically used for smaller projects or less intricate designs. These cutters require skilled operators who can manage the nuances of manual cutting, making them ideal for businesses where flexibility is key. A report from MarketsandMarkets suggests that the handheld plasma cutter market is expected to reach USD 2.5 billion by 2025, reflecting a growing demand for accessible cutting solutions in smaller workshops. Meanwhile, hybrid models combine features of both CNC and handheld systems, offering versatility that can cater to a diverse range of fabrication needs, which can be particularly beneficial for small to medium-sized enterprises.

Understanding these differences is vital for making an informed decision that aligns with your business goals. Whether prioritizing automation, cost-effectiveness, or versatility, each type of plasma table has distinct advantages that can impact your operations significantly.

5 Essential Tips for Choosing the Perfect Plasma Table for Your Business

| Type of Plasma Table | Cutting Capacity | Software Compatibility | Max Thickness | Price Range |

|---|---|---|---|---|

| Entry-Level Plasma Table | Up to 1 inch | Basic Software | 0.25 inch | $5,000 - $10,000 |

| Mid-Range Plasma Table | Up to 2 inches | Advanced CAD Software | 0.5 inch | $15,000 - $30,000 |

| Industrial Plasma Table | Up to 5 inches | Full Suite Software | 1 inch | $40,000 - $100,000 |

| Portable Plasma Table | Up to 0.5 inch | Basic Design Software | 0.125 inch | $2,000 - $5,000 |

| Heavy-Duty Plasma Table | Up to 10 inches | Customized Software | 2 inch | $80,000 - $200,000 |

Budgeting: How to Choose a Plasma Table That Fits Your Finances

When it comes to investing in a plasma table for your business, budgeting is an essential factor to consider. Start by determining your financial limits, as plasma cutting machines can range in price from a few thousand to tens of thousands of dollars. Analyze not only the initial purchase cost but also potential ongoing expenses, such as maintenance, consumables, and operational costs. It's crucial to assess how each model aligns with your budget while meeting your production needs.

Next, consider the return on investment (ROI) that a plasma table can provide. A higher initial cost may lead to a more efficient and durable machine that can handle larger workloads, increasing your production capacity and reducing downtime. Look for features that enhance productivity, such as automation options and software compatibility, which may justify a higher price tag. By carefully weighing these factors, you can make a sound decision that supports your business’s financial health while acquiring the right plasma table to elevate your operations.

The Importance of Customer Support and Warranty for Plasma Tables

When selecting the perfect plasma table for your business, it’s crucial to prioritize customer support and warranty. A high-quality plasma table is a substantial investment, and having access to robust customer service can significantly impact your operational efficiency. Seek manufacturers that offer comprehensive support, including technical assistance and product training. An experienced support team can help you troubleshoot issues quickly, minimizing downtime and ensuring your production process remains smooth.

Moreover, a solid warranty is an essential aspect that should never be overlooked. A warranty not only protects your investment but also reflects the manufacturer’s confidence in their product’s durability. Look for warranties that cover both parts and labor, providing peace of mind as you incorporate a plasma table into your business operations. Knowing that you have support to fall back on when unexpected problems arise makes choosing the right plasma table a less daunting task, allowing you to focus on growing your business with the assurance that you’re equipped with reliable tools.

Customer Support and Warranty Insights for Plasma Tables

Related Posts

-

7 Compelling Reasons Why the Best Plasma Table Will Transform Your Production Line

-

Emerging Trends for 2025: The Rise of Best CNC Plasma Cutting Tables in Manufacturing Efficiency

-

How to Maximize After-Sales Support for the Best CNC Table and Minimize Repair Costs

-

What is the Future of the Best Small CNC Plasma Tables in Global Manufacturing?

-

Maximizing Your Investment: The Benefits of After-Sales Support for the Best CNC Plasma Cutting Machines

-

Unlocking Efficiency: The Unique Advantages of Small Plasma Cutting Tables in Modern Manufacturing