The Future of Industrial Cutting Tables Redefining Precision and Efficiency in Manufacturing

In the rapidly evolving landscape of manufacturing, the role of the industrial cutting table has become increasingly crucial in redefining precision and efficiency. According to a recent report by the Global Market Insights, the industrial cutting table market is projected to surpass $3 billion by 2027, driven by advancements in automation and technology that enhance production capabilities. As manufacturers strive to meet the growing demand for high-quality, customized products, the need for cutting-edge solutions becomes paramount.

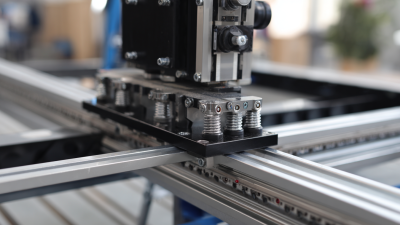

Industrial cutting tables are now equipped with sophisticated features such as CNC technology, which allows for unparalleled precision and reduced waste during the cutting process. This ultimate guide will explore the innovations shaping the future of industrial cutting tables, including the integration of smart technology and sustainability initiatives, positioning manufacturers to thrive in a competitive market.

Advantages of Advanced Cutting Technology in Modern Manufacturing

In today's fast-paced manufacturing landscape, advanced cutting technology is revolutionizing the way industries approach precision and efficiency. One of the significant advantages of these modern cutting tables is their ability to enhance material utilization. By employing sophisticated algorithms and automated processes, manufacturers can minimize waste, ensuring that more raw material is converted into usable products. This efficiency not only lowers costs but also contributes to a more sustainable production cycle, aligning with the increasing focus on environmental responsibility.

Furthermore, the integration of advanced cutting technology enables unparalleled accuracy in manufacturing. High-definition cutting and laser-guided systems allow for intricate designs and detailed patterns that were previously unattainable with traditional methods. This precision ensures that components fit together seamlessly, reducing the need for rework and improving overall product quality. As a result, manufacturers can meet the growing demands for tailored solutions without sacrificing speed or output, positioning themselves as leaders in an increasingly competitive market.

Enhancing Precision: How Cutting Tables Improve Quality Control

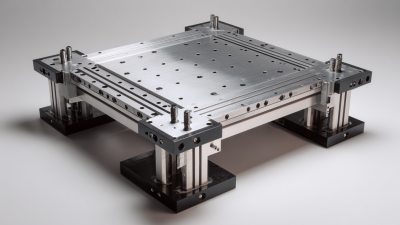

In the fast-paced world of manufacturing, precision is paramount, and cutting tables are at the forefront of enhancing quality control. These sophisticated machines offer unparalleled accuracy, allowing manufacturers to achieve tighter tolerances and reduce material waste. Advanced features such as automatic recalibration, real-time monitoring, and integrated feedback systems ensure that every cut is executed perfectly, minimizing human error and maximizing productivity. By consistently delivering precise dimensions, cutting tables help maintain the integrity of the assembly process, leading to a higher quality end product.

Moreover, the adaptability of modern cutting tables addresses diverse material types and complex designs. This flexibility is crucial in industries where customization is key, as it allows quick adjustments and modifications without sacrificing quality. Advanced software solutions also enable better tracking of production metrics, ensuring compliance with industry standards and enhancing overall operational efficiency. As manufacturers continue to embrace innovation, the integration of high-performance cutting tables will undoubtedly play a significant role in redefining quality control processes, paving the way for a new era of manufacturing excellence.

Boosting Productivity: The Time-Saving Benefits of Automated Cutting

Automated cutting technology has revolutionized the manufacturing landscape, enabling businesses to enhance productivity and precision significantly. According to a recent report by Grand View Research, the global market for automated cutting solutions is expected to reach $6.5 billion by 2025, driven by industries that require high-precision operations, such as textiles and automotive. By reducing manual intervention, these systems minimize human error and optimize cutting patterns, resulting in materials savings of up to 20%.

Tips for adopting automated cutting tables include investing in high-quality software that integrates seamlessly with your existing machinery. This ensures smooth operation and maximizes efficiency. Also, consider training your workforce to operate these advanced tools effectively, as expertise in automated systems can lead to significantly faster project turnaround times.

In addition, regular maintenance of cutting equipment is crucial. Keeping machinery in top condition not only extends its lifespan but also maintains the cutting accuracy essential for high-quality output. The trend towards automation is not merely a luxury; it has become a necessity for manufacturers aiming to stay competitive in an increasingly fast-paced market.

Versatility in Manufacturing: Adapting Cutting Tables for Various Materials

The versatility of modern industrial cutting tables is transforming the manufacturing landscape, adapting seamlessly to an array of materials from traditional metals to advanced composites. As technology evolves, these cutting tables incorporate sophisticated features that allow for precise cutting of diverse materials, including concrete and fiber-reinforced composites. Machine learning is playing a pivotal role in this evolution, optimizing the performance of these cutting systems to handle complex shapes and intricate designs.

The integration of artificial intelligence into the manufacturing process further enhances the efficiency and accuracy of cutting operations. With the ability to analyze vast amounts of data, AI-driven systems can predict material behavior during cutting, ensuring optimal results with minimal waste. This adaptability not only improves productivity but also encourages manufacturers to explore innovative materials, fostering a new era of creativity and efficiency in industrial applications. As the industry embraces these advancements, cutting tables are becoming indispensable tools in the quest for precision and versatility in manufacturing.

Sustainability in Production: Eco-Friendly Aspects of Cutting Table Innovation

The cutting table industry is undergoing a significant transformation, particularly in the realm of sustainability. Recent reports indicate that by 2025, the global market for eco-friendly manufacturing solutions is projected to reach $640 billion, driven largely by innovations that reduce waste and enhance resource efficiency. Manufacturers are increasingly adopting cutting tables designed with sustainable materials and processes that minimize environmental impact. For instance, cutting tables using advanced composite materials not only reduce weight and emissions during production but also enhance the longevity of the product, thereby decreasing the frequency of replacements.

Moreover, the integration of advanced software into cutting table operations has optimized cutting patterns, leading to significant reductions in raw material waste. According to a study by the International Journal of Advanced Manufacturing Technology, companies utilizing smart cutting tables have reported up to a 30% decrease in material waste, translating into substantial cost savings and a more sustainable production cycle. As manufacturers invest in eco-friendly cutting technologies, they are not only adhering to regulatory demands but also responding to growing consumer preferences for sustainable products. This shift not only contributes to environmental preservation but also positions companies as leaders in the competitive landscape of the manufacturing industry.

The Future of Industrial Cutting Tables: Sustainability in Production

This chart illustrates key performance metrics for modern industrial cutting tables, focusing on sustainability aspects in production. The data showcases material efficiency, energy consumption, waste reduction, and the percentage of recyclable materials, underscoring the industry's shift towards eco-friendly practices.

Related Posts

-

How to Maximize After-Sales Support for the Best CNC Table and Minimize Repair Costs

-

Innovative Uses of the Best CNC Table in Modern Manufacturing Solutions

-

Finding Quality Suppliers for Best Industrial Cutting Tables Effective Strategies for Global Buyers

-

Ultimate Guide to Selecting the Best Industrial CNC Plasma Table for Your Business

-

Emerging Trends for 2025: The Rise of Best CNC Plasma Cutting Tables in Manufacturing Efficiency

-

Maximizing ROI on Best Industrial CNC Plasma Tables: How Superior After-Sales Service and Low Maintenance Costs Drive Success